Gents,

I recently purchased an E70 X5M and it was debadged when it was delivered. I don’t think I’m too much of a badge nut but I do care for the ///M symbol if it looks appropriate. I didn’t care for the early aftermarket fix of only putting a stock ///M badge on the front grill, but preferred the refined look of the newer F85 badges as they were subtle and unassuming. I could not find a readily available badge for the E70 X5M so I began to plan a DIY. I had most of the parts in my garage already so I built a list.

PARTS:

-OE BMW X5M lettering from an F85

https://www.ecstuning.com/b-genuine-...k/51138063149/

https://www.amazon.com/dp/B07GNTT4R9...c-bd00a11f7ffb

-Sheet Metal from ACE Hardware (I think I used 1/8” Sheet Metal that was left over from fabricating Hawaii registration sticker plates)

-Bolts from Home Depot (They were standard 1/4” zinc bolts and nuts which were long since I intended to cut them)

-Black silicon caulk (used to prevent marring on the exterior of the grill)

-Metal epoxy (I used Loctite instead of JB Weld based upon reviews)

-Gloss black rust preventive spray paint (Used ACE Hardware brand left over from registration sticker plates)

-Gloss Clear coat enamel (left over from painting calipers)

TOOLS:

-Drill

-Drill bits (I used a smaller bit for pilot holes and a 1/4” bit for the actual holes but the size will be based upon your bolt size)

-Dremel

-Dremel Sander attachment

-Dremel metal cutter

-Angle Grinder (Only needed if you have a battery powered dremel. A plug in dremel with metal cutter will easily handle the job and your cut will be straighter.

-1000-3000 Grit Sandpaper (You should try and step it down to make the finished product look good)

-Vice or vice grips or C-clamp (used to hold the metal while cutting and drilling)

-Wooden block to drill into

-A square measuring device

IMG_1927

IMG_1927

STEP 1: CUT THE METAL

I determined that the best size based upon the lettering size was 2-3/4” X 3/4". I measured this out and marked the cuts on the steel using a sharpie marker and the square. I first tried using the dremel but the battery was crappy so I used my angle grinder.

IMG_1928

IMG_1928

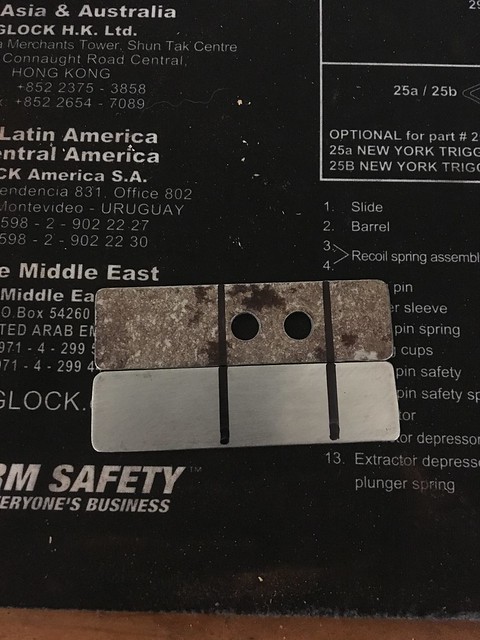

STEP 2: SAND, MARK, AND DRILL THE HOLES

I used the dremel and sander attachment to sand the corners and edges of the plates smooth then used the sand paper to remove the rust and prepare the surface of the plates. DO NOT use the dremel on the flat surfaces or you may cut deep into the plates. The Grill slats slope off to the right so to balance the lettering visually the bolts must be offset. I did a few quick measurements and marked them on the plates. This OFFSET portion is appropriate for the FACEPLATE ONLY. I learned this only after install so THE PICTURES ARE INACCURATE. The faceplate will have the bolts secured with epoxy offset but the rear plate will need to have the holes centered. Use the available space between the lines (slat opening) to mark the holes. I secured the plate with a C-clamp, drilled pilot holes, then drilled the actual holes.

IMG_1929

IMG_1929

IMG_1930

IMG_1930

IMG_1932

IMG_1932

IMG_1934

IMG_1934

STEP 3: CUT AND EPOXY THE BOLTS

I held the bolts in place behind the front plate and placed the assembly on the grill to measure the appropriate length of the bolts. I then cut the bolts at the appropriate length (approximately 1-1/2" from the plate surface for the final cut including the heads) Using the available space I set the bolts onto the metal surface and planned how to set them so that they would account for the curvature of the slats and allow the plate to sit flat. I mixed the epoxy and set the bolts using the nuts and back plate to ensure they would set straight. I cannot stress enough ALLOW THE BOLTS AND EPOXY 24 HRS TO SET. I realized later that my original cut had the bolts too long and this led to the epoxy breaking while I tried to cut it.

IMG_1935

IMG_1935

STEP 4: PREP AND PAINT THE PARTS

I sectioned off a bit of the bolts to allow the nuts to go on easily, but this is not necessary if you have cut to the appropriate length. I added 4 coats of black and 3 coats of clear waiting the appropriate 3 min between black coats and 10 min between gloss. Again, I cannot stress enough ALLOW 24 HRS FOR PAINT TO DRY AFTER THE LAST COAT. I was impatient which led to wrinkles.

IMG_1936

IMG_1936

IMG_1939

IMG_1939

STEP 4: APPLY SILICON

I applied a decent amount of black silicon caulk to the REAR of the faceplate and the rear plate and spread it with tooth picks (The rear is not needed or recommended since it is visible it will be better to keep a gloss finish). The silicon can be difficult to manage and aggravating so be careful and remain patient. I don’t have a picture of this step because I was too angry while doing it to snap one.

STEP 5: TEST FIT

If you have been lucky enough to get it this far without messing it up then make sure to test fit the item before applying the lettering…this will save you the only important and indispensable part: the lettering itself. (I messed up the bolt length but already applied the lettering and handling the assembly, not allowing drying time for the enamel or the epoxy, led to wrinkles in the enamel and breaking of the epoxy.)

STEP 6: APPLY THE LETTERING

Good news, the lettering carrier is the same size as the faceplate, that’s why I chose that size. Simply align it and press hard for a few seconds; I used a drilled bit of wood as a stand while I applied it.

IMG_1943

IMG_1943

STEP 7: INSTALL

Open the hood, place the faceplate where you want it vertically in the grill, put on the rear plate, apply Loctite on the rear of the bolts and tighten down the nuts. Enjoy!

IMG_1945

IMG_1945

IMG_1946

IMG_1946

IMG_1947

IMG_1947